Many people believe SAP's strength is in its powerful, individual modules. The real power comes from how those pieces connect and communicate with each other. Without that connection, you just have a collection of expensive software silos.

A strong SAP SD integration transforms a set of tools into a smooth, end-to-end business process. The SAP SD module is often the starting point for this entire sales process. It's where customer interaction begins, kicking off a chain of events that ripples through your entire organization.

Thinking about your SD integration as an afterthought is one of the biggest mistakes during an implementation. You'll learn how this module acts as the central hub, linking your sales activities directly to your supply chain, finances, and production floor.

SAP SD and MM Integration — From Sales to Supply

When a sales order is created in the SD module, it is more than a record of a potential sale. It is a promise to your customer, and that promise must be backed by actual inventory. This is where the tight link between Sales & Distribution (SD) and Material Management (MM) becomes so important.

The first point of contact is the Availability to Promise (ATP) check. When you enter an order, the system instantly queries the MM module to see if you have the product on hand. It looks at current stock levels, planned receipts from production or vendors, and other demands to give a realistic delivery date.

Once the order is ready to ship, creating an outbound delivery in SD triggers a series of actions in MM. This process reserves the material for that specific customer order. Then, when you perform the Post Goods Issue (PGI), it generates a material document in MM, using movement type 601 to officially deduct the stock from your inventory of finished goods.

As a project manager on multiple global rollouts, I've seen this link in action countless times. In retail and wholesale distribution projects, a solid mm sd integration means the right product ships at the right time. It helps minimize stockouts that lose sales and prevents the buildup of excess inventory that ties up cash.

This integration also handles more complex situations like third party orders. An item with category TAS in a sales order can automatically generate a purchase requisition in MM. The system knows you don't stock the item and need to buy it from a vendor to ship directly to the customer.

Returns are another area where SD and MM work together, with return orders triggering stock movements back into your warehouse. Put simply, SD tells the system what to move, and MM handles exactly how and where it moves.

SAP SD and FICO Integration — Turning Orders into Revenue

A sale isn't complete until the money is in the bank. The SAP SD and FICO (Finance and Controlling) integration makes sure that every sales activity is accurately reflected in your company's financial records. This connection, often called sd fi integration, is non-negotiable for accurate financial accounting.

The most critical touchpoint happens when you create a billing document in SD. As soon as the invoice is saved, the system automatically creates a corresponding accounting document in the FI module. This single action posts revenue to your profit and loss statement and creates a receivable in your customer account, which hits a specific reconciliation account.

But the fi-sd integration starts even earlier. During the sales order process, credit management checks the customer's credit limit in real-time with data from the FI Accounts Receivable (FI-AR) module. If a customer is over their limit, the system can block the order until it's approved. This prevents you from shipping goods to customers who may not be able to pay.

The revenue account determination process is another vital link. SD uses a determination procedure with multiple factors to figure out which General Ledger (G/L) accounts to post to. A small mistake in this configuration can send revenue or receivables to the wrong accounts, causing huge headaches for your accounting team and FICO consultants.

This procedure uses a condition technique similar to the pricing procedure. It uses access sequences to search for valid records based on criteria like customer account assignment group and material account assignment group. This finds the correct GL Account to post accounting entries for revenue, discounts, or surcharges defined by an account key.

Here is a simplified view of how the system can define account assignments:

| Application | Condition Type | Sales Org | Cust. Acct. Grp. | Mat. Acct. Grp. | Account Key | G/L Account |

|---|---|---|---|---|---|---|

| V | KOFI | 1000 | 01 (Domestic) | 01 (Finished) | ERL (Revenue) | 800000 |

| V | KOFI | 1000 | 02 (Export) | 01 (Finished) | ERL (Revenue) | 800100 |

| V | KOFK | 1000 | 01 (Domestic) | 01 (Finished) | ERL (Revenue) | 800000 |

Finally, data flows from SD into the Controlling (CO) module for profitability analysis (CO-PA). Every sales transaction can carry details that help you analyze profitability by customer, product, or region. This feeds into profit center accounting, letting you see which parts of your business are actually making money with a clear view of the cost of goods sold versus the revenue.

SAP SD and PP Integration — From Customer Order to Production

For companies that make their own products, the connection between sales and the factory floor is essential. The SAP SD and Production Planning (PP) integration bridges the gap between customer demand and your manufacturing operations. This link makes sure that you build what customers want, when they want it.

This is most obvious in Make-to-Order (MTO) and Engineer-to-Order (ETO) scenarios. In these cases, a sales order created in SD doesn't pull from existing stock. Instead, it directly creates a production order in the PP module, launching the manufacturing process for that specific customer's request.

Even in Make-to-Stock (MTS) environments, SD demand plays a huge role. Sales orders and sales forecasts from SD are key inputs for Material Requirements Planning (MRP). The MRP run analyzes this demand, checks available inventory, and creates planned orders to tell the production team what needs to be made. These planned orders are then converted into production orders.

This integration provides a critical feedback loop. Availability and capacity checks during order creation look at the PP module to see if the production schedule can handle the new demand. It stops your sales team from promising delivery dates that the factory can't meet. The costing for the finished goods, often based on a standard price, also flows from production to finance for variance analysis.

When the production team confirms progress on a production order in PP, that information can be sent back to SD, signaling that the goods are ready for delivery. On heavy manufacturing projects I've led, I've seen how ETO sales orders linked to PP orders are crucial. This connection ensures that custom-built products are costed correctly and delivered on time as part of a complex development process.

The Core of Your SAP SD Integration Architecture

The SAP SD integration isn't just a few simple links. It's a backbone of data that flows through your entire system, coordinated by SD. Think of SD as the process orchestrator, making sure everyone has the information they need to do their job.

This all starts with shared master data. Information like the material master is used by everyone. SD uses it for sales views, MM for purchasing and storage views, PP for production views, and FICO for accounting views. They are all looking at the same single source of truth for each product, which is a critical concept for any enterprise resource planning system to succeed.

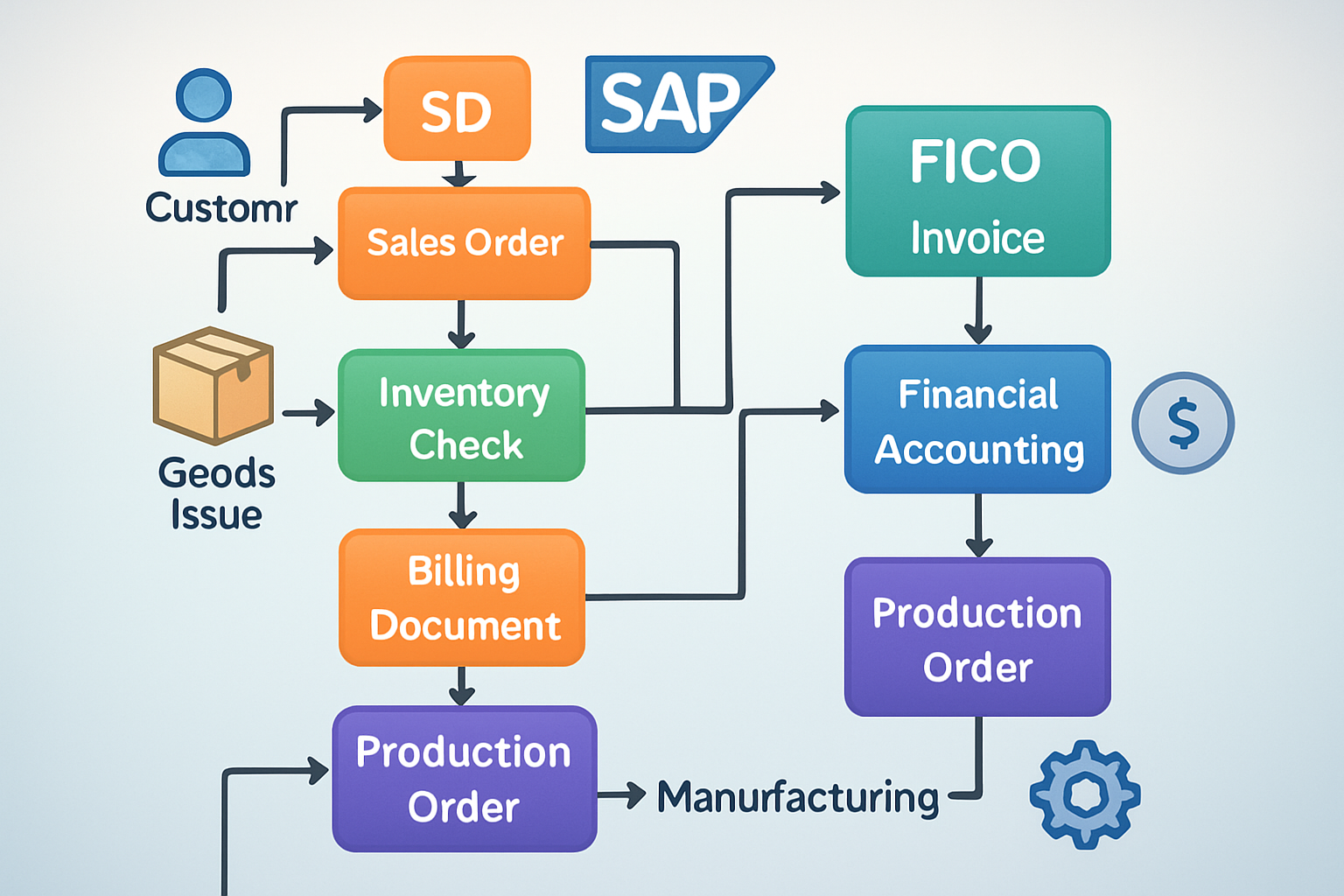

Here's how the data flows in a typical transaction:

- Sales Order (SD): Creates the initial demand and captures customer information.

- Delivery (SD & MM): Triggers the reservation and physical movement of goods.

- Billing (SD & FICO): Creates the invoice and triggers the financial postings.

- Accounting Document (FICO): Records the revenue and customer receivable in the G/L accounts.

- Production Order (PP): Is often triggered by the sales order in MTO scenarios.

Under the hood, this is managed by cross-module tables and documented processes. Shared data structures like VBAK for sales document headers and BKPF for accounting document headers allow the system to function as a unified whole. A document posted in SD has immediate effects in the SAP finance modules.

With the move to SAP S/4HANA, this has become even more streamlined with the Universal Journal, or table ACDOCA. This provides real-time data access across financial and logistic processes. This simplifies the architecture and removes many reconciliation steps previously needed between the different modules.

Common Integration Pitfalls (and How to Avoid Them)

Even with SAP's powerful tools, integration projects can go wrong. The problems usually aren't technical bugs. They are almost always caused by process and data issues that were overlooked during implementation.

Here are some of the most common traps I've seen:

- Inconsistent Master Data: If a material's valuation class is wrong in the material master, FICO postings will fail every time you ship it. Keeping master data clean is job one.

- Missing Configuration: A missing setting in the account determination procedure or a bad tax code can bring the entire order-to-cash process to a halt.

- Poor Process Timing: Running batch jobs for billing documents before the goods issue transactions have been processed can cause a cascade of errors. The sequence of operations matters.

- Ignoring Data Migration: If historical customer account data or open orders are moved incorrectly during a go-live, it can cause immediate integration failures. Proper data migration planning is essential.

- Siloed Project Teams: The biggest issue I see is when the SD, MM, and FICO consultants don't talk to each other. Many integration problems start not in SAP, but from implementation teams that work in silos.

The Project Manager's job is to force communication and unify the configuration across all modules. The key to avoiding these issues is thorough testing and clear communication between business departments. The finance team needs to understand the logistics process, and the sales team needs to understand the financial impact of their actions.

Why Integration is a Business (Not Just Technical) Imperative

Strong SAP SD integration directly impacts your company's performance and profitability. When these modules work together seamlessly, you get real, measurable business results. It's not just about making the IT department happy.

Tightly integrated processes lead to a reduced order cycle time. This means you can get products to your customers faster. It also leads to improved inventory accuracy, so you're not tying up money in a bank account for stock you don't need or losing sales because of unexpected stockouts.

Perhaps most importantly, it gives you enhanced cash flow visibility. You have a clear, real-time picture of the entire process, from a customer promise all the way to profit realization. An integrated system shows you where your business stands at any given moment.

Conclusion

SAP SD is much more than just a sales module. It is the nerve center of your ERP system, connecting the promises you make to customers with the operational reality of your supply chain, production lines, and financial books. Getting the fi sd integration right is fundamental to building a transparent and efficient business.

When information flows freely between your front-office and back-office operations, you create a powerful engine for growth. The seamless connection between sales, logistics, and your general ledger makes your entire operation more responsive and profitable. Every account posting becomes a clear reflection of a real-world business event.

Ready to connect your sales, logistics, and finance processes in one flow? Partner with SAP BW Consulting.

Need Expert SAP Consulting Expertise?

We are team of top-level SAP consultants, focused on helping you get the most value from your SAP investment. Whether you need a single SAP SD consultant or an entire team of SAP experts, we can provide them. Please our book a meeting service to get started.