Whether your company creates cars, develops software, or offers consulting services like my team at SAP BW Consulting, Inc., chances are you’ve heard the buzz about “lean” processes. You probably know the goal: get rid of waste and deliver value. Sounds great, right? But actually *doing* that gets tricky.

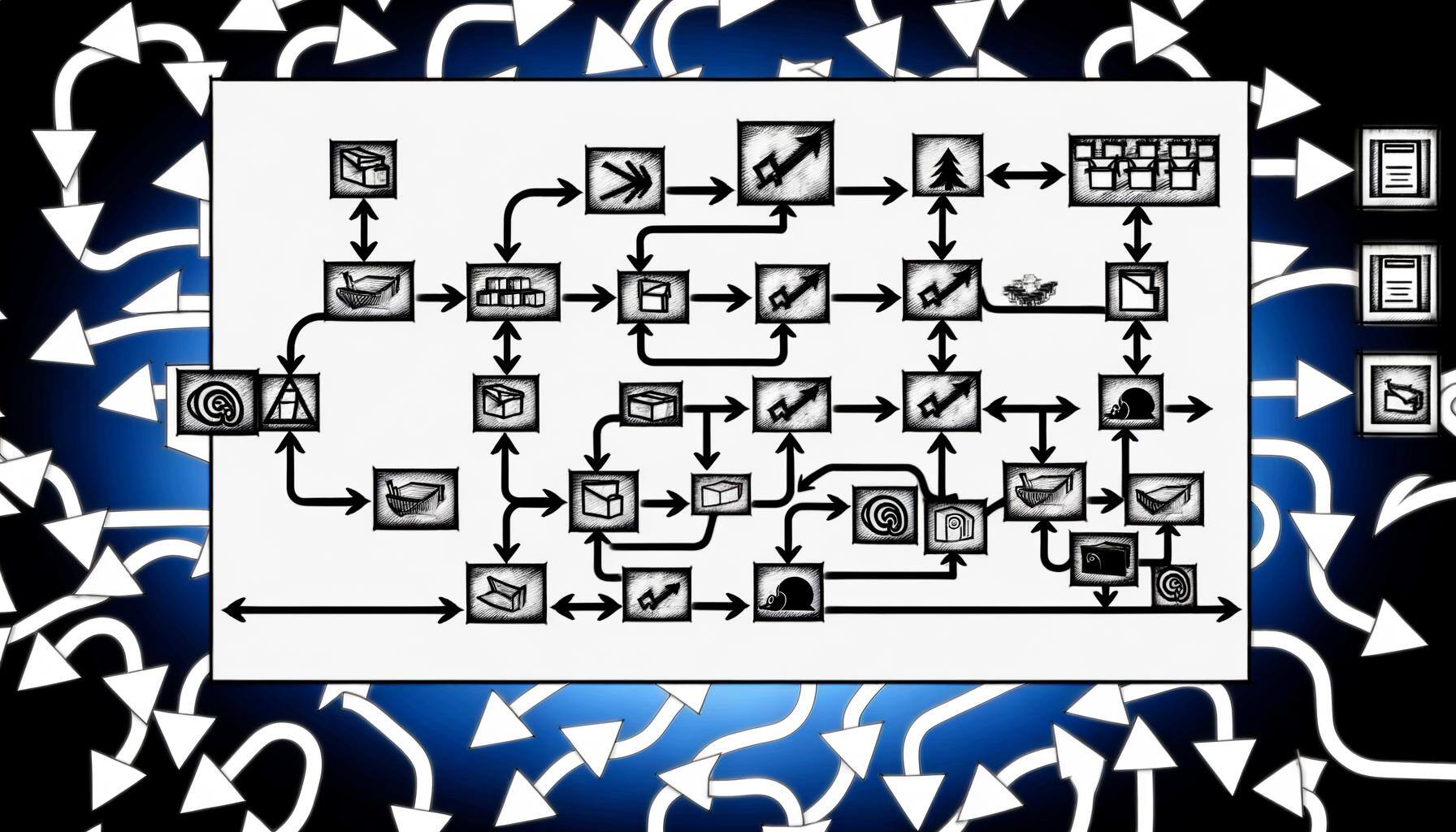

That's where value stream mapping steps in as a seriously handy process improvement tool. Think of value stream mapping as a GPS for your business. Imagine plotting every single step it takes to get a product from the initial spark of an idea to your customer’s hands.

You analyze how information flows, spot the annoying roadblocks, and then… bam. You’ve got a roadmap to a leaner, meaner, more efficient operation.

Value Stream Mapping: What Is It Really?

Okay, let's ditch the marketing hype for a sec and break it down. Value stream mapping, at its core, is a visual flowchart technique. But this isn’t about tracking every single task like you might with a regular flowchart.

Value stream mapping focuses on one product or product family. Think of it like zooming out to see the big picture—not just individual actions. As we learned on the Lean Enterprise Institute website, this method forces you to map two things simultaneously: the actual flow of materials and how information zips around your organization.

The magic really happens when those two things come together visually. Suddenly, you *see* bottlenecks. You notice where communication gets stuck.

.png?width=4908&height=3828&name=Value%20Stream%20Mapping%20Explained_%20How%20To%20Guide%20With%20Examples%20-%20visual%20selection(1).png)

Why Visualizing The "Value Stream" Matters

Why go to all the trouble of drawing pictures? Can't we just *think* about our processes? Experience says: no.

Frankly, most companies aren’t very good at recognizing waste when it's hidden in their daily grind. Value stream mapping yanks back the curtain on those hidden inefficiencies. Plus, it's visual.

Putting everything down on paper (or a digital whiteboard) does a few powerful things:

- Exposes Waste: It’s crazy easy to overlook unnecessary steps, inventory pileups, or delays when you're knee-deep in the day-to-day. Visualizing things forces you to confront those inefficiencies head-on.

- Sparks Collaboration: Have you ever noticed how cross-functional teams *love* to point fingers when things go wrong? Value stream mapping makes it tougher to play the blame game. When everyone's staring at the same map, it shifts the conversation towards solutions, not excuses. Plus, the visual element breaks down silos. It gets everyone on the same page, speaking a common language, working together toward a shared goal: delivering that customer value.

- Makes It Real (and Actionable): Let’s be honest. Abstract plans rarely get executed well. But a visual representation of a messed-up process, with all its warts on full display? It becomes undeniable, creating that much-needed sense of urgency to take action.

.png?width=6204&height=4836&name=Value%20Stream%20Mapping%20Explained_%20How%20To%20Guide%20With%20Examples%20-%20visual%20selection(2).png)

Putting It To Work: Creating Your Value Stream Map

I’ve walked through this process dozens of times, both internally with my team at SAP BW Consulting, Inc., and alongside our client companies struggling with their production processes. This process applies if you are using value stream mapping with software engineering teams or something more tangible, such as supply chain optimization.

The fundamentals always remain the same. Let's explore the key steps involved in creating a value stream map.

Key Steps

- Pick a Product Family: Don't try to boil the ocean. Choose one specific product, service, or family of related items for your mapping exercise. Otherwise, things get too complicated. For instance, one of my first value stream mapping sessions with a manufacturing client was to streamline the assembly process for their best-selling high-precision small electric motors.

- Assemble the Crew: You need folks from every stage that touches this product or service—design, production, sales, customer service, etc. Diverse perspectives = more accurate map. Plus, having multiple people contribute increases buy-in later because no one likes a solution forced upon them. At SAP BW Consulting, Inc. we believe that getting all stakeholders bought-in on day one makes our jobs of implementation a million times easier in the future. Aim for about ten people, keeping it small enough to manage while large enough for a variety of inputs. Include key external suppliers when relevant because that outside perspective can be gold.

- Walk It Like You Talk It (“Gemba Walk”): Grab your comfy shoes, some Post-Its, and hit the "gemba" (that’s the Japanese term for “the real place,” and it’s way cooler than saying “shop floor”). Seriously, you (or, better yet, your whole team) need to physically *see* how materials and information flow *in reality*. Don’t just guess or rely on dusty process documents. Talk to people who actually do the work because there’s always more to it than meets the eye.

- Draw It Out—and Collect the Data: You are basically creating a visual timeline with this product family or service at the center. This visual representation captures everything. You've got materials, information zooming back and forth, process boxes to depict major stages… it can look messy. Use the standard VSM symbols for extra clarity because visuals matter for collaboration. But while doing this, don’t get so focused on drawing that you forget data. Every process box should have real data attached to it – things like cycle times, wait times, inventory levels, those sorts of metrics. You’re after a true picture of performance, not assumptions.

- Highlight Waste Hotspots: The fun begins. Start spotting bottlenecks and delays—it's honestly a bit like playing detective. Look for areas of overproduction where more resources are consumed without greater output. Think back to the Lean methodology and the six key areas of waste: Overproduction, Inventory, Motion, Waiting, Over-Processing, Defects, and Transportation. Often what seemed like "just the way we've always done things" suddenly screams "we can fix that." during value stream mapping.

- Don't Just Complain; Craft Solutions (and Then… Iterate): Now take that “current state” map and draw out the ideal "future state." Envision the most efficient flow. It often takes a series of “future state maps” to achieve a truly optimized workflow. It's an iterative journey with many refinements over time. This is all about identifying concrete steps—reorganizing work areas, creating better communication systems, implementing tech to smooth things out… whatever it takes to make your future state a reality. For one software development client, the seemingly simple task of installing shared, accessible repositories for code eliminated countless handoffs and delays (that caused friction within the team).

.png?width=5628&height=5484&name=Value%20Stream%20Mapping%20Explained_%20How%20To%20Guide%20With%20Examples%20-%20visual%20selection(3).png)

Remember, It's All About Eliminating Waste

Much of what makes value stream mapping such a valuable part of business process consulting is that it helps people focus on the process - not the people.

Here's how that happens:

Focus on Production Flow

As you first create your value stream map, and collect process data, you will eventually have enough data to calculate TAKT time. As you work to eliminate waste, TAKT time will be naturally reduced. How cool is that!

Driven by Customer Requirements

Value stream maps should be driven, and this is hard, by customer requirements. You have to learn to ask yourself how each process step is being driven by a customer requirement.

Reducing Lead Times

With continuous delivery of improvements, you will see a reduction in lead times and a reduction in the amount of raw materials you have to keep on hand. This, in-turn, will reduce your inventory carrying costs. It will also improve your on-time product delivery rate.

Get Your Team Members Involved

While my team and I pride ourselves on our ability to perform value stream mapping of any process, we always find more success when we keep your team members heavily involved. The time required for the value stream mapping process and the quality of the value maps depends directly on the engagement of the people who 'touch' the process day-in and day-out.

Value Stream Mapping Helps Build "Process Ownership"

We find they not only know how their work process really works, they also have many ideas on how to improve them. But until someone came along and asked them for their ideas, they often didn't feel compelled to share them. Call it the Hawthorne effect, or something else, but here is where you uncover the 'golden nuggets' of knowledge they all have

Your Value Stream Management Experts

Once you've got your team onboard with the idea of value stream mapping, then you're ready to move onto the critical on-going stage of value stream management. This is where the power of continuous improvement comes in to play. Remember the rule of 70, if you improve a process by 1% a day, in 70 days, you'll will doubled it's output.

Current Map vs Future Map

Finally, it's always a good idea to keep the idea of As-Is vs To-Be in mind, a term you will often hear in software development. But in this case, it's critical to keep in mind that while your initial value stream map looked at how things are 'now', it often takes completely capabilities to reach next level performance benchmarks. A future-state value stream map can help you determine the steps required to achieve this.

Release Those Creative Sparks of Genius

Remember: value stream mapping isn't a “one and done” activity. It's meant to spark continuous improvement. Keep that spirit alive. Implementing efficiency methods, like those identified in a value stream mapping session, can lead to substantial gains.

.png?width=3756&height=3252&name=Value%20Stream%20Mapping%20Explained_%20How%20To%20Guide%20With%20Examples%20-%20visual%20selection(4).png)

Conclusion

Look, change is tough—no doubt about it. We humans often resist it. It's scary because the unknown can cause so much anxiety.

But value stream mapping isn't some theoretical management fad. It is practical. A great starting point is by creating even a small, quick-and-dirty value stream mapping session that produces valuable insights.

And oftentimes, when leaders see real-world inefficiency on a piece of paper (or digital screen), it kickstarts that powerful cultural shift toward true customer-centricity that we should be striving for. Every step in the process, from identifying waste to streamlining information flow, contributes to this shift.

FAQs About Value Stream Mapping

What Are the Four Steps of Value Stream Mapping?

Although most professionals identify between six to eight distinct steps within the process, it really boils down to four: 1.) Identifying the value stream or area that will be improved. 2.) Creating the Current State Map. 3.) Creating the Ideal (Future) State Map, and 4.) Developing an action plan for improvement and then, iterating as needed.

What are the three types of VSM?

Three common types are Production Family VSM (for single-product lines), Design-to-Launch VSM (focused on new product development) and the broader organizational VSM, which maps a company's core processes.

What is value stream mapping for dummies?

Essentially it is a collaborative technique using visual diagrams to break down every single step it takes for an idea to become something valuable a customer actually wants. Its aim? Eliminate the “stuff that adds zero value.” That could mean excessive inventory, ridiculous delays, even internal communication breakdowns, anything that slows your company down. It's a very focused form of process mapping, that relies on both process data and the expertise of your people. By identify and measuring each process step, you can move into the world of lean manufacturing.

Is value stream mapping Lean or Six Sigma?

This one’s tricky because both prioritize waste reduction. You'll often hear about “Lean Six Sigma,” blending those methodologies. However, their origins are slightly different. While Lean originally blossomed from the efficient Toyota Production System after World War 2, focusing on eliminating anything that didn’t add value from the *customer’s* perspective—Six Sigma started in the 80s at Motorola, taking a more data-driven approach.

I actually visited the Motorola STU III telephone manufacturing facility in Seguin, Texas after they had just won the Malcom Baldridge Award for quality. They had radically increased their production volume by. drastically improving each step of their production process, and quickly implementing measurable improvements, which largely came from the shop floor workers. By being able to identify waste, production process variations, and performing rapid production process improvement experiments, they had virtually eliminated quality problems, and dramatically improved product flow.

Conclusion

While you can find value stream management professionals to help you develop your value stream map implementation plan, the key with value stream mapping is action and follow-through. A visual model allows us to easily pinpoint the biggest areas that need fixing and allows for prioritization for future refinement and value delivery.

About SAP BW Consulting, Inc.

SAP BW Consulting, Inc. provides comprehensive SAP solutions, including SAP Business Intelligence (BI) and SAP Business Warehouse (BW) consulting, SAP ABAP development, and project management. Our services also include a 1099 Contractor Invoicing and Payment Management System, Salesforce consulting, and Balanced Scorecard consulting for strategic planning. As HubSpot Marketing and Sales Partners, we specialize in Google Ads, Facebook Ads, LinkedIn Ads, Account-Based Marketing, Content Marketing, and Ecommerce solutions, including Shopify.

Ready to optimize your operations and strategy? Book a meeting with us.